The World’s smallest LBS Light Engine

We develop integrated light engines both as projection display systems and as 3D depth sensing solutions. They feature unmatched display quality, exceptional 3D sensing abilities as well as minimal power consumption and system size.

Our light engines are based on laser beam scanning and utilize our proprietary 2D MEMS mirrors. High-performance laser sources (RGB, IR) ensure exceptional brightness and contrast for unparalleled display quality even in broad daylight, without compromising eye safety. We incorporate our own optics and ASICs to further minimize the footprint and power consumption of the entire system.

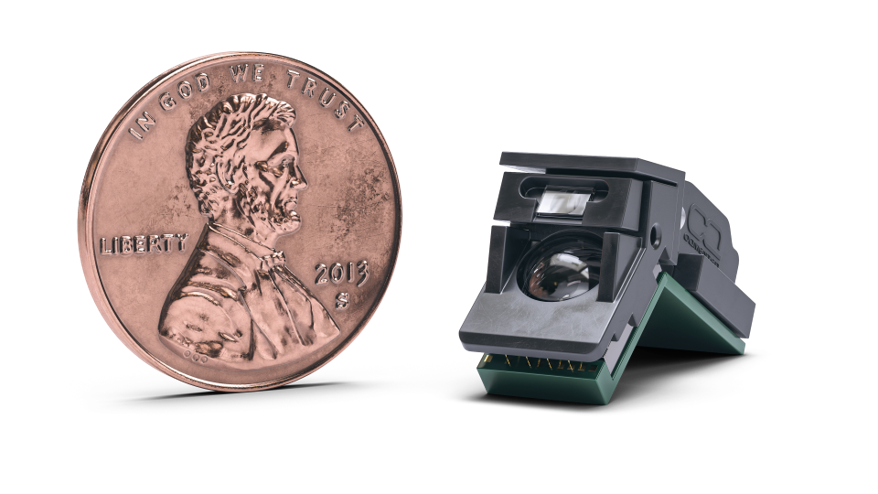

UltraLITE XR™

We introduced our fully integrated light engine in Las Vegas during CES 2024. It is designed for high-volume production and has a market entry date slated for end of 2025. We will bring this light engine to market as complete plug and play solution.

• Brightness: 19 lm

• Size: 1.2 ccm

• Power consumption: <200 mW (sparse content)

For technical inquiries, please use our sales contact form.

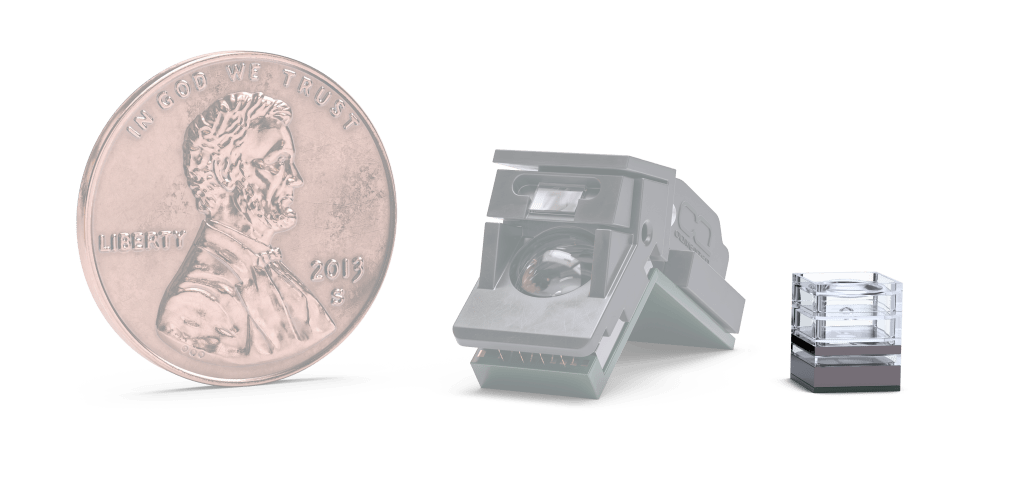

UltraLITE XR™ Gen2

We are working on a true manufacturing paradigm shift: our next generation light engine will be integrated completely on wafer level. This enables the simultaneous integration of up to 1,000 light engines and involves a significant reduction in the engine’s size as well as in production costs. It has potential to entirely disrupt microdisplay manufacturing.

• automation replaces manual work

• parallel manufacturing of up to 1,000 light engines

• unmatched level of miniaturization

• unprecedented cost reduction

modularity

Our LBS light engines were developed specifically for Augmented Reality glasses. However, just as Augmented Reality isn’t limited to glasses, our light engines aren’t either, having the potential for ultra low-cost production and scalability: We have advanced our software in such ways that it allows the use of laser beam scanning technology also for other, even entirely different applications by combining multiple light engines.

OQmented light engines are pushing the boundaries of what is possible today: We have developed a technique to “stitch” together the projections of an unlimited number of light engines resulting in one seamless projection and enabling more perspectives for the viewer, more natural colors than in state-of-the-art displays and virtually limitless extension for Field of View, frame rate, brightness and resolution, depending on the application.

This way, our light engines can power projections for AR glasses or head up displays and other automotive lighting, but also for large advertising panels.

Example: The projection of seven light engines are stiched together to form one large image.

BubbleMEMS™ Technology

Most Compact. Low Power. High Optical Performance.

Born out of 25 years of research and development, our BubbleMEMS™ technology platform is the foundation of the world’s smallest, ultra-low power, high-performance display and 3D sensing engines. Enabling display and sensing across XR, automotive and other industries.

All our MEMS mirrors are hermetically vacuum-packaged on wafer level. The vacuum ensures long-term durability as well as maximum performance by reducing the mechanical losses of the mirror oscillation and achieving Q-factors 10x higher than state-of-the-art. In combination with our sophisticated electronics for drive and control, we achieve a power consumption below 10 mW.

Our MEMS chips feature scan frequencies up to 100 kHz, a large mirror diameter range allowing huge apertures, and ultra-wide scanning angles of 180° optical Field of View. Our extensive MEMS production experience for classic designs but also for novel MEMS concepts, allows performance beyond state-of-the-art. The production process is effectively designed for high-volume production.

Lowest Power Consumption

Up to 180° FOV

Large Mirror Diameter Range

kHz Interlace Frame Rate

High Display Quality

High Fidelity Motion Rendering

Compared to conventional LBS systems, which often use two mirrors, featuring one fast and one slow axis, our 2D MEMS mirrors incorporate two resonant axes, both operating at high frequencies. The resulting Lissajous scan pattern realizes an energy efficient way of scanning a big FOV and a high sampling rate, generating superior image quality.

Lissajous scanning samples several hundreds of subframes extremely quickly, providing for smooth motion rendering. However, improper operation of the Lissajous trajectory causes artifacts for the viewer in 3D perception of fast-moving objects. Our control system allows for optimal adjustment to the respective use case, overcoming these perception artifacts through precise trajectory control.